Fiberglass, commonly referred to in the context of furniture as glass fiber reinforced plastic (GFRP), is a composite material composed of fine glass fibers woven into a fabric and bonded together with a plastic resin. The defining characteristic of fiberglass is its combination of strength and lightweight, making it a popular material for a variety of furniture pieces, from outdoor patio sets to sleek, modern interior chairs and tables. Here's a closer look at the properties, production process, advantages, and disadvantages of fiberglass as a furniture material:

Properties:

- Strength and Durability: The glass fibers provide significant tensile strength, while the plastic resin matrix distributes stress over a larger area, resulting in a material that can withstand substantial loads and impacts without fracturing.

- Lightweight: Despite its strength, fiberglass is relatively lightweight compared to metals and solid wood, which can make furniture easier to move and handle.

- Weather Resistance: Fiberglass has excellent resistance against corrosion, water, and UV radiation, which prolongs its life and is ideal for outdoor applications.

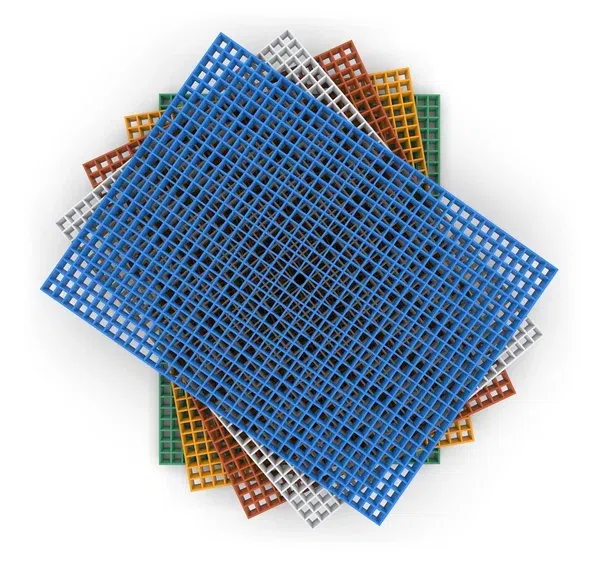

- Moldability: It can be formed into complex and intricate shapes that are not feasible with traditional woodworking or metal forging, allowing for unique design possibilities.

- Low Thermal Conductivity: The material insulates well against heat, maintaining a comfortable touch and not becoming too cold or too hot based on environmental conditions.

- Non-Conductive: It doesn’t conduct electricity, which can be a beneficial property for certain applications.