Moso bamboo (Phyllostachys edulis) is a species of bamboo that has grown in popularity as a material for weaving and furniture-making due to its sustainability, strength, and versatility. As a furniture material expert, I will describe the properties, manufacturing process, and typical applications of Moso bamboo weaving material.

Properties of Moso Bamboo:

Sustainability: Moso bamboo is one of the fastest-growing plants on Earth, capable of reaching full maturity in just 4 to 5 years. This makes it a highly renewable resource for crafting furniture, with a smaller environmental footprint compared to traditional hardwoods that take decades to mature.

Strength and Durability: Bamboo fibers are naturally strong and have a high tensile strength similar to some metals, making Moso bamboo a durable option for furniture. It is also resistant to swelling and shrinking when exposed to variations in temperature and humidity.

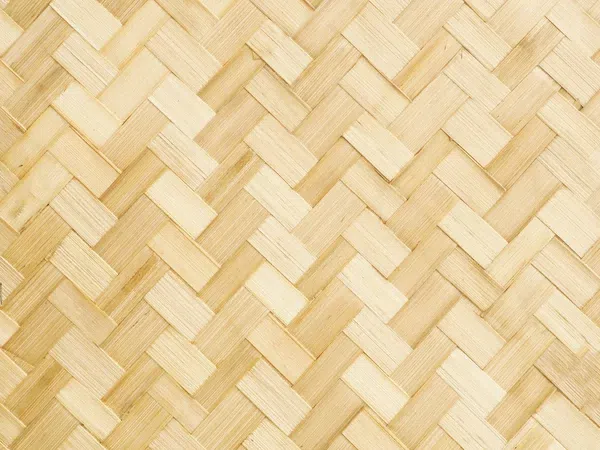

Aesthetic Appeal: The natural color of Moso bamboo ranges from pale yellow to light green, and it can be treated to achieve various shades and finishes. Its grain is usually straight and can be highlighted with finishing treatments to enhance its visual appeal.

Although strong, Moso bamboo is also quite flexible, making it amenable to various weaving techniques which can be used to create intricate designs and patterns in furniture.