Silicone foam rubber is a versatile material frequently used in the furniture industry for various applications, particularly where cushioning, sealing, or thermal and acoustic insulation are necessary. It combines the properties of both silicone and foam, yielding a unique set of characteristics that make it suitable for furniture-making and other applications.

Composition and Production:

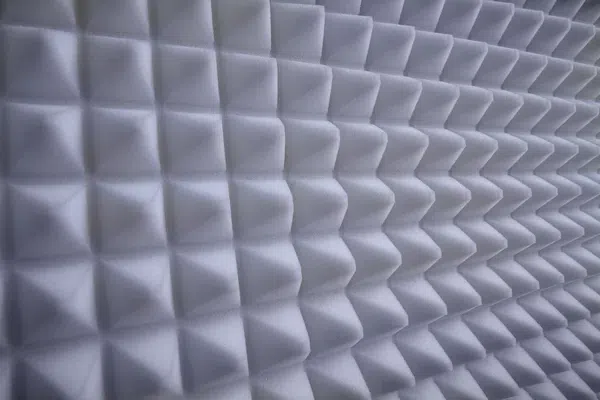

Silicone foam rubber is produced by adding a foaming agent to liquid silicone. This agent introduces air bubbles into the material, causing it to expand and create a cellular structure once cured. The curing process can be provoked by heat or at room temperature, depending on the type of silicone and the foaming agent used. The result is a lightweight, porous material that can range from a very soft to a medium firm consistency.

Key Characteristics of Silicone Foam Rubber:

Temperature Resistance: It has a broad operating temperature range, usually between about -55°C to 300°C (-67°F to 572°F), making it suitable for applications subjected to extreme heat or cold.

Durability: Silicone foam is known for its longevity, resisting degradation from environmental factors such as ozone, ultraviolet light, and oxygen.